Products

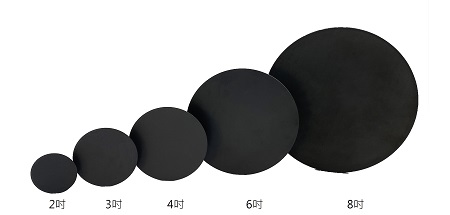

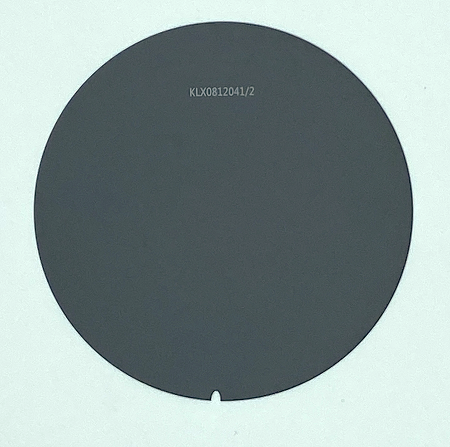

SiC carrier

SiC carrier

Detailed Description

Application

Extreme thin wafer is often placed on SiC carrier connected to a vacuum generator,

and the wafer is fixed by vacuum suction.

It is convenient for waxing, thinning, dewaxing, cleaning and cutting processes

in the field of semiconductor and optoelectronic industries.

Feature requirements

1. Good thermal conductivity to shorten the process time of waxing and dewaxing, improve

production rate, and increase production efficiency

2. The pore size is small and well distributed, and evenly adsorbs each small localized

2. The pore size is small and well distributed, and evenly adsorbs each small localized

region of the whole wafer

3. Acid and alkali resistance

3. Acid and alkali resistance

Why is Kallex better than others

1. Various sizes and specifications can be customized

2. Having good flatness, parallelism, the smooth surface, and will not scratch the wafer

3. Stable quality and fast delivery

2. Having good flatness, parallelism, the smooth surface, and will not scratch the wafer

3. Stable quality and fast delivery

>

>